Prototyping and Integration

Prototyping and Integration

Prototyping a design can prove a system is functional, increase the TRLs and MRLs, and is an integral step in the “System Engineering V” product development process.

The complex prototyping and integration process can be an overwhelming experience filled with technical, cost, and schedule risks. Unrealistic lead times and extraordinarily high costs lead your team to rely on manufacturing companies that you have no experience with; their quality of components and responsiveness has not been proven to you, ultimately putting your project at risk.

McCormick Stevenson helps our customers who have procurement departments setup for ongoing production, not optimized for prototype quantities and schedule. These rapid prototyping procurement efforts can distract internal resources, potentially jeopardizing existing production schedules as well as the schedule of the development effort.

McCormick Stevenson offers agile prototyping and integration solutions to our Customers.

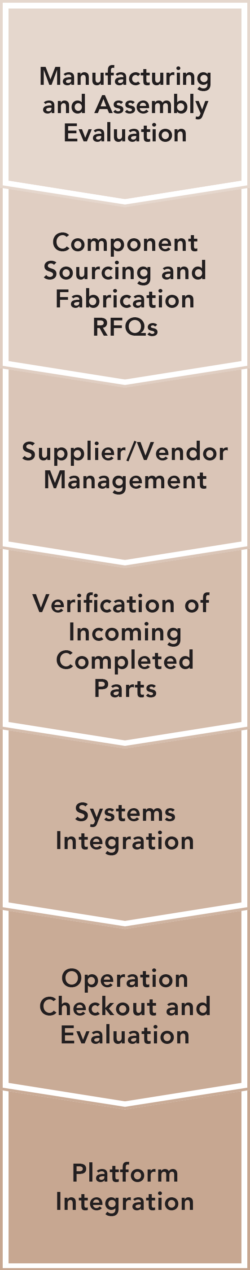

MCCST can help our customers through the entire prototyping and integration process.

MCCST can help our customers through the entire prototyping and integration process.

McCormick Stevenson has the skills and tools to successfully test and qualify through physical prototyping. In doing so, McCormick Stevenson will engage with our wide network of electrical and mechanical manufacturers to manage cost and schedule for even the most complex prototyping efforts.

The fabricators we work with specialize in quick-turn and low quantity manufacturing that is necessary to meet our customers technical and schedule requirements. Our engineering team can provide constructive design feedback to mitigate common prototyping and integration risks. McCormick Stevenson’s metrology lab can inspect the component dimensions to verify fitment of the assembly before integration is started, catching derivations from the drawings.

We proactively collaborate with fabricators to answer questions quickly, avoiding schedule slip or errors that can negatively impact the program. MCCST can help integrate the system in the laboratory or in the field; we can come to your location with the tools necessary for platform assembly or host the system integration at our facility.

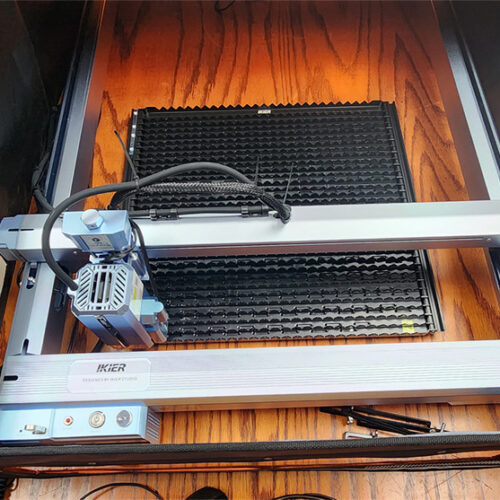

MCCST’s internal 3D printing, resin printing, and laser cutting capability can bring down cost and schedule as well, depending on the project requirements. Our agility and responsiveness allow us to meet a wide range of challenges while ensuring on-time delivery of the optimal solution.

Engage McCormick Stevenson for your prototyping and integration effort to gain access to expansive capabilities and experience the value we continue to bring to our customers!

Our Capability

Our Capability

- Design manufacturability review

- We will ensure the design is readily manufacturable and help develop approaches for challenging areas

- Design and assembly evaluation

- We will verify mechanical interfaces to certify compatibility with the system and platform

- Rapid iterative design (early and late stage)

- Leveraging additive processes through our manufacturing contacts, as well as internal additive manufacturing and laser cutting capability

- Manufacturing/fabrication process development

- We will engage with the fabricators to develop processes that meet the expectations of the TDP

- Rapid material procurement and component sourcing

- Our wide network of industry contacts gives us access to the quickest material/component sourcing available

- Metrology / CMM part inspection

- Verification of mechanical fitment as the parts are delivered can bring down schedule risk associated with respins

- System integration

- Our Team is equipped to integrate the prototype system at a customer specified location or hosted in our integration area at MCCST

- Platform integration

- We will support the integration of the prototype system into the next higher assembly wherever the platform may reside

- Experiment design and evaluation

- The operational checkout process can provide immediate feedback on the functional success of the prototype system.Taking into consideration the requirements and verification procedures, MCCST can derive experiments to establish initial success indications, eliminate TBDs remaining in the requirements, and gain insight in how the prototype will perform on the platform.