Analysis & Simulation

Analysis & Simulation

Will it work? In the digital product development environment, Analysis and Simulation are critical to answering that simple question. At McCormick Stevenson, our Team offers access to the technical expertise and modern tool-set required to confront the challenge, and we do so with a deliberate focus on Armament Systems. Through such focus, we continuously grow and enhance our knowledge of both the physics at hand, as well as the unique operating environment confronting cannon-launched or missile-borne electro-mechanical systems—including extraordinary levels of thermal, shock, and vibration loading.

Customer Collaboration Throughout the Design Process

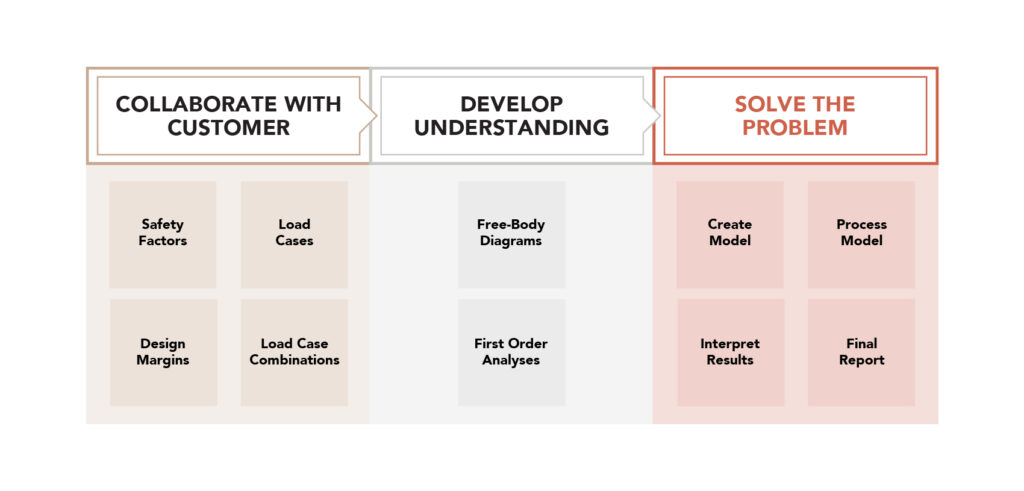

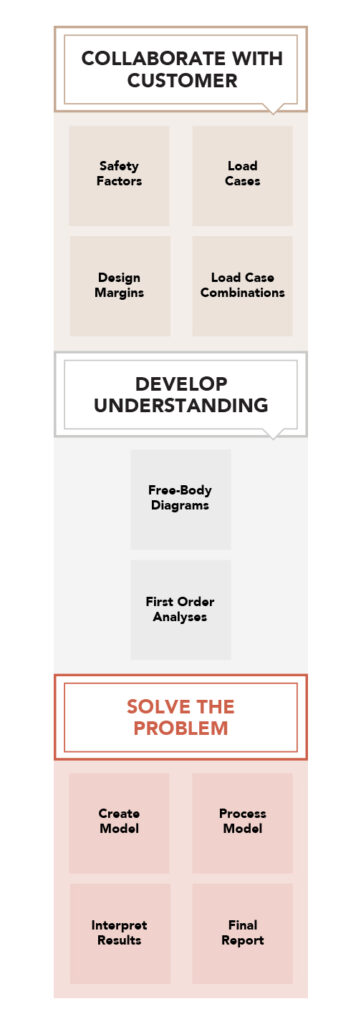

McCormick Stevenson takes a comprehensive and holistic product development approach, which is why we collaborate with our partners on the preliminary information gathering and analysis prior to modeling. Our team works closely with partners to define all aspects of the problem, including critical failure modes, loading environments, required safety factors, materials of construction, design margins, etc.

We then construct appropriately detailed models to determine one of three project outcomes: overdesigned, under-designed, or marginally designed. The chart below highlights our process, which includes constant communication, adjustments, and review throughout.

McCormick Stevenson Performs Analysis Across the Product Development Cycle

Industry leaders partner with us during the preliminary design stage to guide concept development, during final design to verify specification compliance, and during testing to validate analysis models and support the testing team. To meet these needs, McCormick Stevenson offers analysis expertise that includes:

- Finite Element Analysis (FEA)

- Computational Fluid Dynamics (CFD)

- FMECA (Failure Modes, Effects & Criticality Analysis)

- Tolerance analysis using both worst-case and statistical methods

- Design-to-Analysis data interoperability and optimization

- Shape/topology optimization

- Analysis of 3D-printed components including light weight lattice structures

- Static & transient structural analysis (including modal, shock & vibration)

- Steady state & transient heat transfer analysis

- Aerodynamic heating

- Reliability analysis, and more…

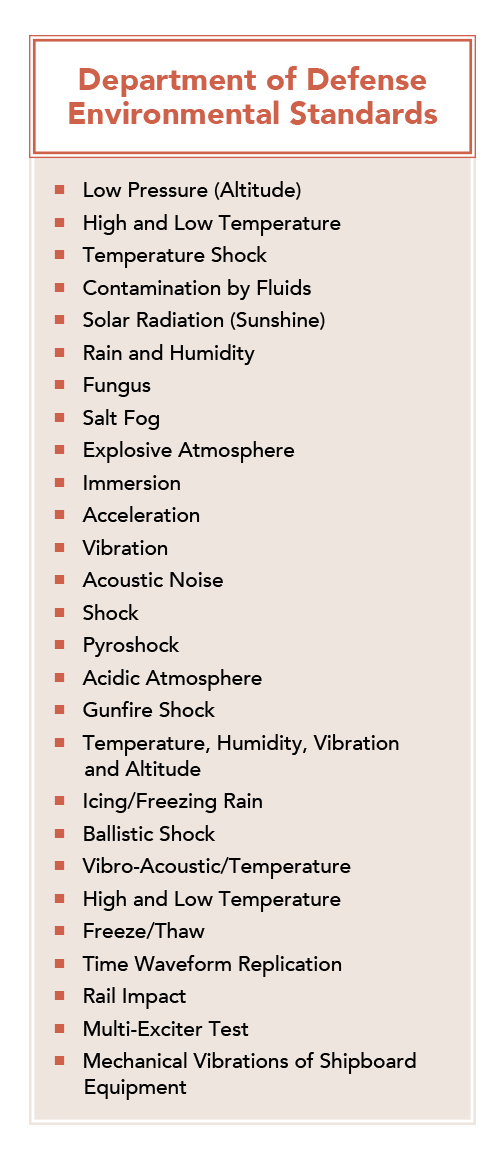

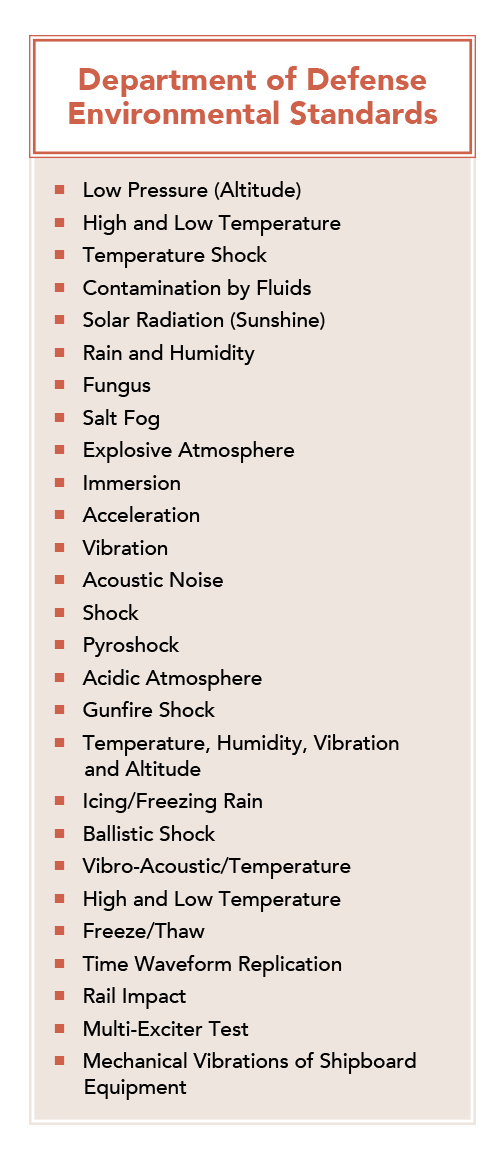

Expertise with DOD Environmental Standards

McCormick Stevenson specializes in understanding and applying all conditions and requirements associated with extreme military environments. Throughout the modeling process we perform analysis iteration and results interpretation to either validate our designs or identify necessary changes.

McCormick Stevenson Performs Analysis Across the Product Development Cycle

Industry leaders partner with us during the preliminary design stage to guide concept development, during final design to verify specification compliance, and during testing to validate analysis models and support the testing team. To meet these needs, McCormick Stevenson offers analysis expertise that includes:

- Finite Element Analysis (FEA)

- Computational Fluid Dynamics (CFD)

- FMECA (Failure Modes, Effects & Criticality Analysis)

- Tolerance analysis using both worst-case and statistical methods

- Design-to-Analysis data interoperability and optimization

- Shape/topology optimization

- Analysis of 3D-printed components including light weight lattice structures

- Static & transient structural analysis (including modal, shock & vibration)

- Steady state & transient heat transfer analysis

- Aerodynamic heating

- Reliability analysis, and more…

Expertise with DOD Environmental Standards

McCormick Stevenson specializes in understanding and applying all conditions and requirements associated with extreme military environments. Throughout the modeling process we perform analysis iteration and results interpretation to either validate our designs or identify necessary changes.

A Design Mission to Manage and Reduce Unit Cost

Analysis and Simulation are critical to modern digital product development and enable virtual evaluation of many alternate materials and geometries in support of design trade analysis and risk reduction. In so doing, we better prepare for qualification testing and production while avoiding over-designed components and reducing product cost.

A Design Mission to Manage and Reduce Unit Cost

Analysis and Simulation are critical to modern digital product development and enable virtual evaluation of many alternate materials and geometries in support of design trade analysis and risk reduction. In so doing, we better prepare for qualification testing and production while avoiding over-designed components and reducing product cost.