Manufacturing Inspection Services

In conjunction with our Production Engineering capabilities, McCormick Stevenson offers Manufacturing Inspection Services either in our lab facility or on-site at customer-designated locations. These services include rapid turnaround times and comprehensive documentation. By handling your dimensional inspection needs, we provide outsourcing benefits such as increased flexibility, quicker turnaround, access to industry expertise, reduced labor costs, and improved risk management.

ISO/IEC 17025:2017, PJLA Testing Accreditation #117064

Contract Inspection

- First Article Inspection (FAI)

- Batch Inspection for Key Characteristics

- Capability Studies

- Visual Inspection and Sorting

- Source Inspection

- Turnkey Inspection Systems

- Project Management

- Reverse Engineering

Complete Outsourcing Program

- Part Inspection (rework and final processes as required)

- Interface with supplier regarding discrepancies

and clarifications - Packaging and Shipping to Final Destination

- Dimensional Inspection and Reverse Engineering

Online and Offline CMM Part Programming

- Dimensional Measuring Interface Standard (DMIS)

- Coordinate-Measuring Machine (CMM)

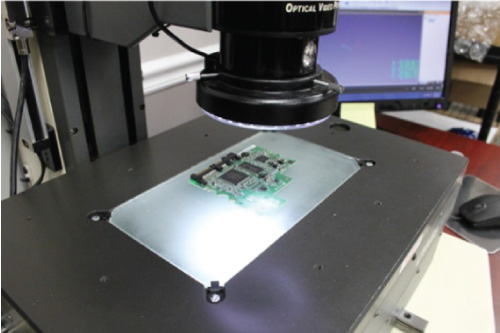

Inspection Services Equipment

McCormick Stevenson uses state-of-the-art equipment for all inspection needs. Below are details on the tools available in our Manufacturing Inspections Lab:

Numerex DCC CMM (40” x 28” x 24”)

- Coordinate-Measuring Machine

- Volumetric Accuracy .00025”

- Renishaw PH9 Probe System

- CMM-Manager Software (Nikon)

Helmel DCC CMM (16” x 20” x 14”)

- Coordinate-Measuring Machine

- Volumetric Accuracy .00020”

- Renishaw PH8 Probe System

- CMM-Manager Software (Nikon)

Standard Inspection Equipment

- Various handheld measuring tools

View or Download McCormick Stevenson’s

Manufacturing Inspection Services Flyer

If you’re facing an upcoming challenge, or have any questions, please reach out to see how McCormick Stevenson can help you deliver.

Bob Neshta, Dimensional Metrology Lab Manager

Phone: (727) 735-9633; 207

Email: inspection@mccst.com