Equipment Design & Automation

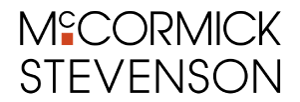

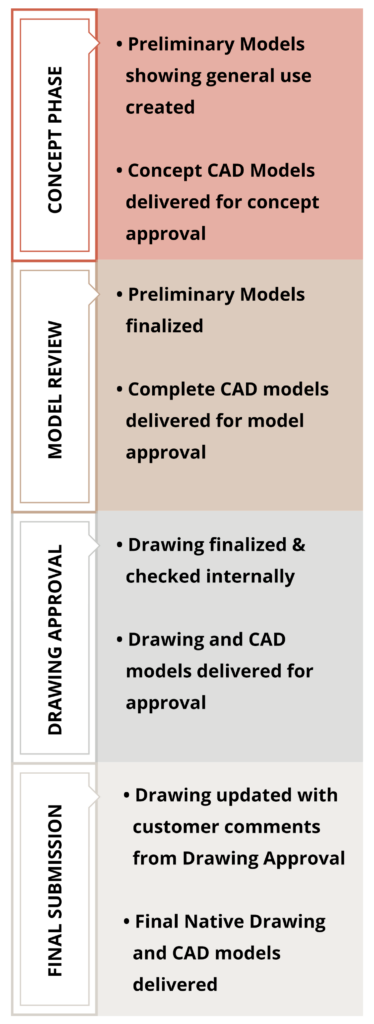

How We Work

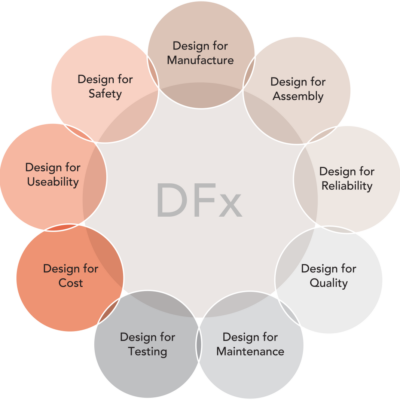

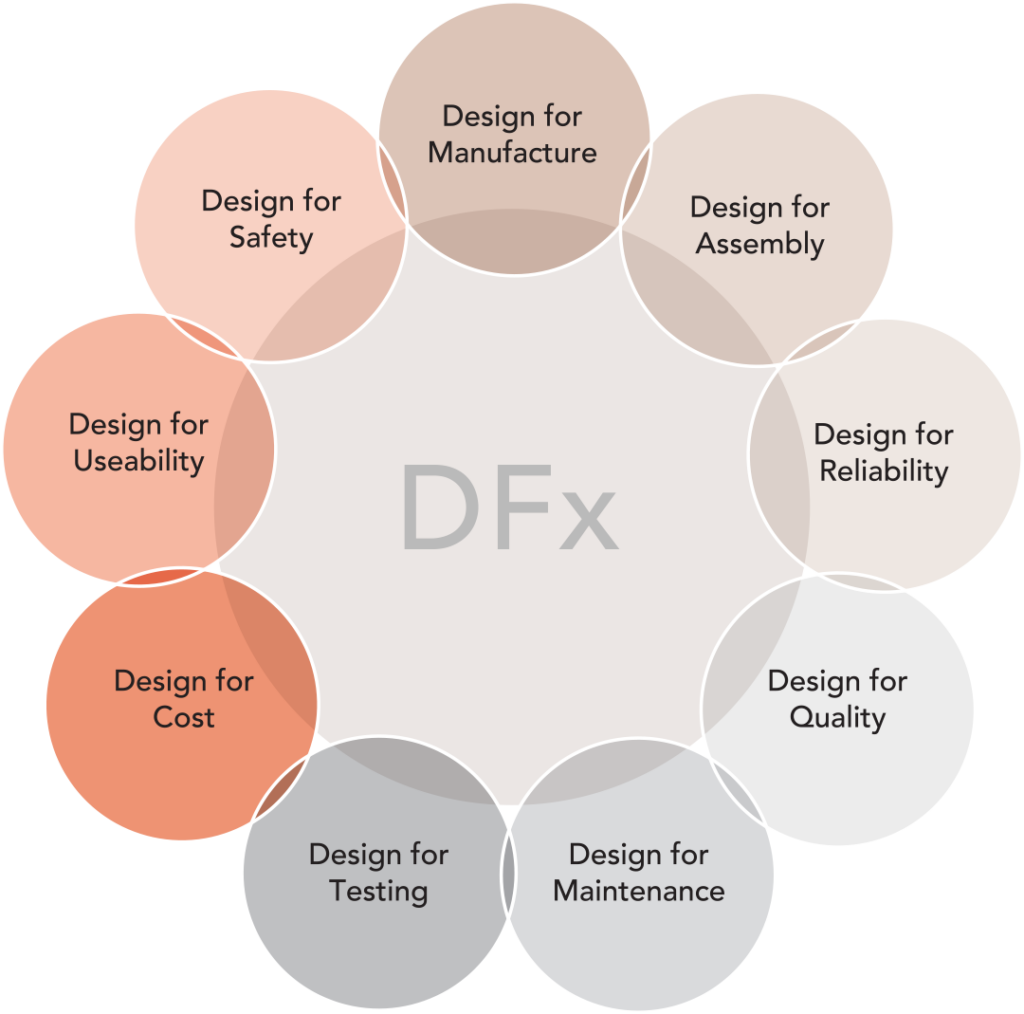

Design for Excellence – Design for Manufacturability, Assembly, Inspection, and Test (DFx)

Design for Excellence – DFx – is not just a concept at McCormick Stevenson. It is the systematic rigor that we embrace for each and every product design from the earliest stages of development. All to provide products that meet requirements and expectations the first time!

Design for Excellence –

Design for Manufacturability, Assembly, Inspection, and Test (DFx)

Design for Excellence – DFx – isn’t just a concept at McCormick Stevenson. It is the systematic rigor that we embrace for each and every product design from the earliest stages of development. All to provide products that meet requirements and expectations the first time!

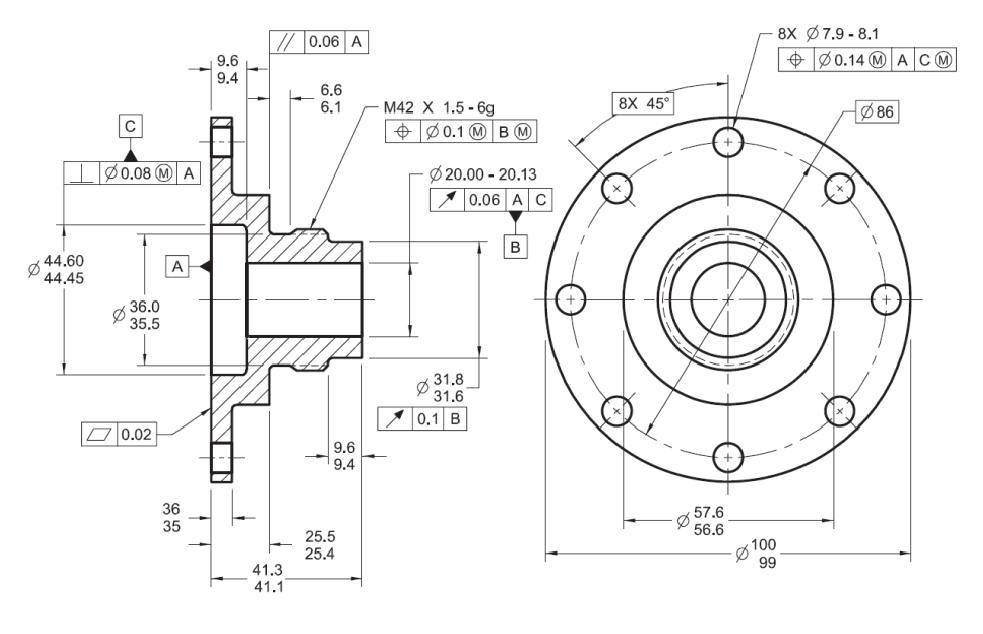

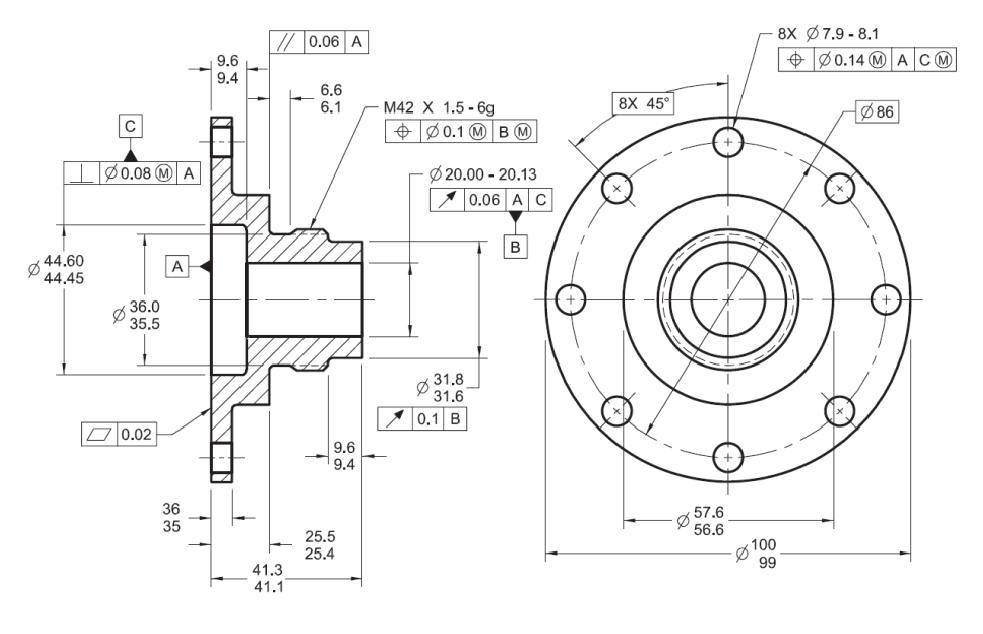

Geometric Dimensioning and Tolerancing

Geometric Dimensioning and Tolerancing – or GD&T — may sound straight-forward, but it is a critical step in product design that can make or break a product by driving:

- Performance

- Function

- Manufacturability

- Assembly

- Cost

Geometric Dimensioning and Tolerancing

Geometric Dimensioning and Tolerancing – or GD&T — may sound straight-forward, but it is a critical step in product design that can make or break a product by driving:

- Performance

- Function

- Manufacturability

- Assembly

- Cost

MCCST engineers specialize in GD&T. Armed with an advanced knowledge of ASME Y14.5-2009 and Y14.5-2018, we know how to establish dimensions and tolerances to achieve the optimal balance between proper function, performance, manufacturability, and cost-effectiveness throughout the point of fabrication through the product’s lifecycle, from fabrication to end-of-life.

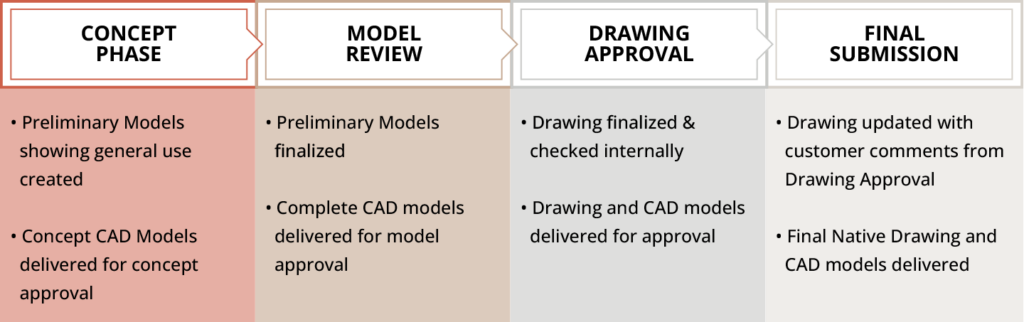

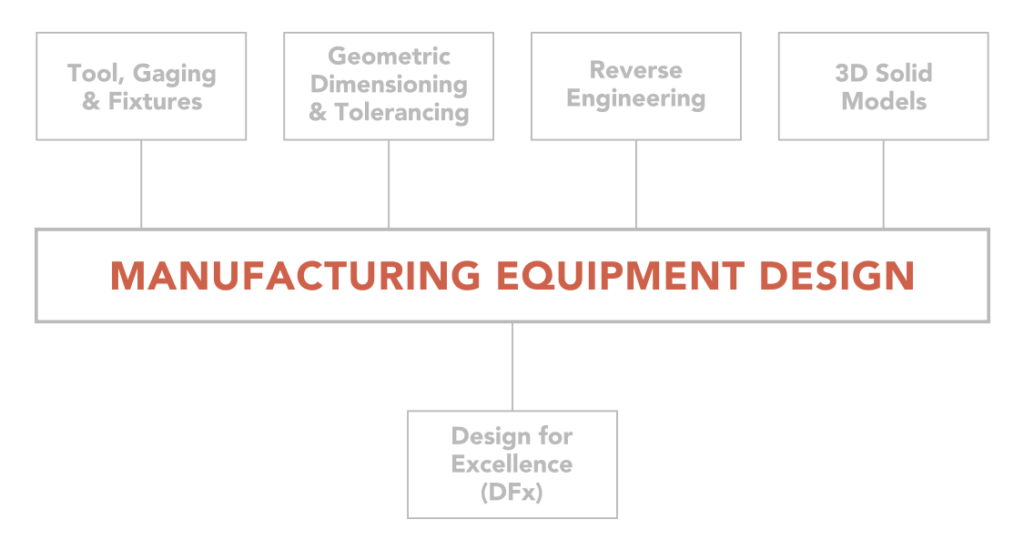

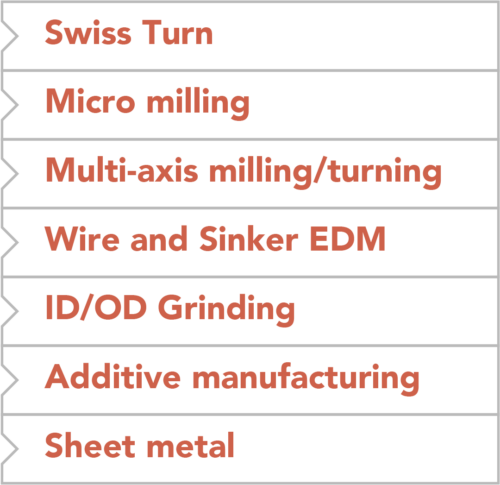

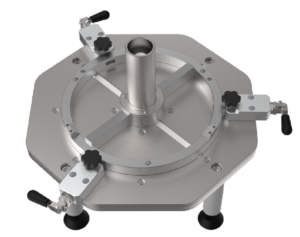

The MCCST Manufacturing Equipment Design applies across manufacturing domains:

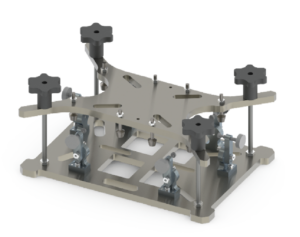

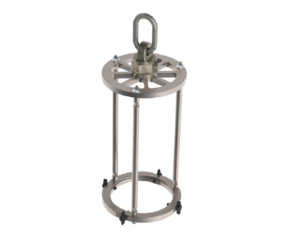

Tooling, Gaging, and Assembly

Tooling, Gaging,

and Assembly

Why? Having correct gages and fixtures are key to manufacturing consistency and efficiency. Together with several partner gage vendors, we ensure that manufacturing has the tools it needs for meeting customer requirements, fabrication processes, and parts acceptance

Types of Gages at MCCST

- Location & Positional gages

- Functional gages

- Bench gages

- Template gages

- Flush pin gages

- Optical comparators

- Comparator Fixtures

- Go/No Go

- Thread gages

- Size gages

- Ring gages

- Perpendicularity

- Concentricity gages

- Arrangement gages

- Limit gages

Engineering Documentation

Documentation is nearly as important as an optimized design and manufacturing process!

On behalf of our customers, MCCST documents it all so that the products can be reproduced with the same quality and attention to detail as the original. Our document is comprehensive and thorough, allowing products to be maintained and managed over an enduring life cycle, and cyclically upgraded for future requirements

Reverse Engineering / 3D Solid Models

MCCST offers the capability to reverse engineer parts – allowing us to build 3D models and drawings, even when design and manufacturing documentation has limited availability.

Why Reverse Engineer?

- Enabling system interoperability with legacy systems

- Factoring out obsolescence

- Modernization

- Repurposing legacy parts to new applications

- Product improvement

- Product documentation

Engineering Documentation

Documentation is nearly as important as an optimized design and manufacturing process!

On behalf of our customers, MCCST documents it all so that the products can be reproduced with the same quality and attention to detail as the original. Our document is comprehensive and thorough, allowing products to be maintained and managed over an enduring life cycle, and cyclically upgraded for future requirements

Reverse Engineering /

3D Solid Models

MCCST offers the capability to reverse engineer parts – allowing us to build 3D models and drawings, even when design and manufacturing documentation has limited availability.

Why Reverse Engineer?

- Enabling system interoperability with legacy systems

- Factoring out obsolescence

- Modernization

- Repurposing legacy parts to new applications

- Product improvement

- Product documentation