Ordnance Handling, Loading, Reloading, & Storage

Ordnance Handling, Loading, Reloading, & Storage

McCormick Stevenson brings proven expertise in the design and manufacture of ordnance and materiel handling systems.

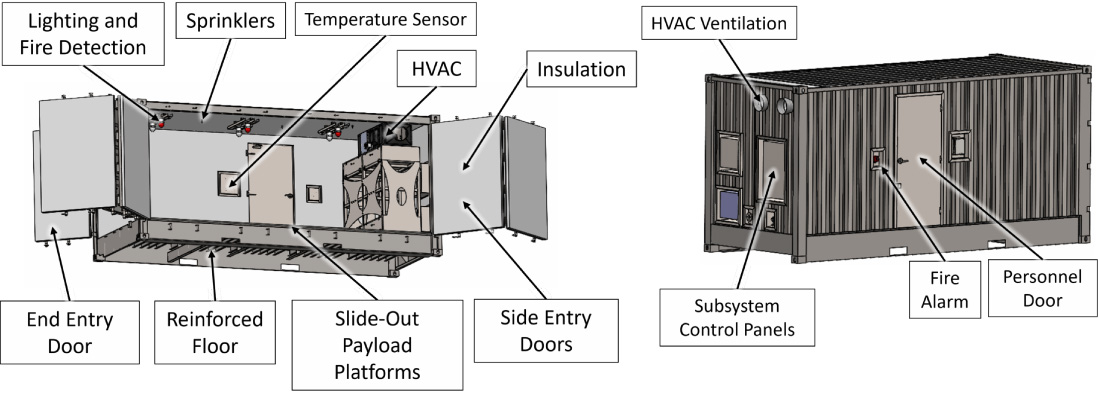

ISO Container Ordnance Storage Magazine

ISO Container Ordnance Storage Magazine

Our ISO Container Ordnance Storage System is designed to comply with MIL-DTL-32525 for Shipboard Portable Magazines and provides a flexible, secure solution for storing and transporting munitions.

- Available in ISO Standard 20 ft. and 40 ft. containers

- Inconspicuous storage for sensitive ordnance, munitions, and energetic materials

- Configurable load-out options to meet program requirements

- No organic dunnage required

Read our recent deployment milestone: McCormick Stevenson delivers advanced ISO shipping container for U.S. Navy

Key Magazine Features

Key Magazine Features

- ISO Standard 40’ container form factor

- Stores/transports four MK 41 Vertical Launch System Canisters of various lengths

- External ship power interface panel

- Side door configuration for forklift loading/unloading

- Tie-down system with all-metal rigging, tested to withstand up to 90° tip

- 40’ ISO Shipping Container is READY NOW

Flexible Container Options

Flexible Container Options

Designed, Analyzed, Tested, Delivered.

- End Entry Doors

- Side Entry Doors

- Optional Features:

- Reinforced Floors

- Slide-Out Payload Platforms

What is your need? We deliver turn-key solutions for custom missile or munition form factors, from requirements development through qualification and production.

Deliverables include:

- End item production

- Qualified Technical Data Packages (TDPs)

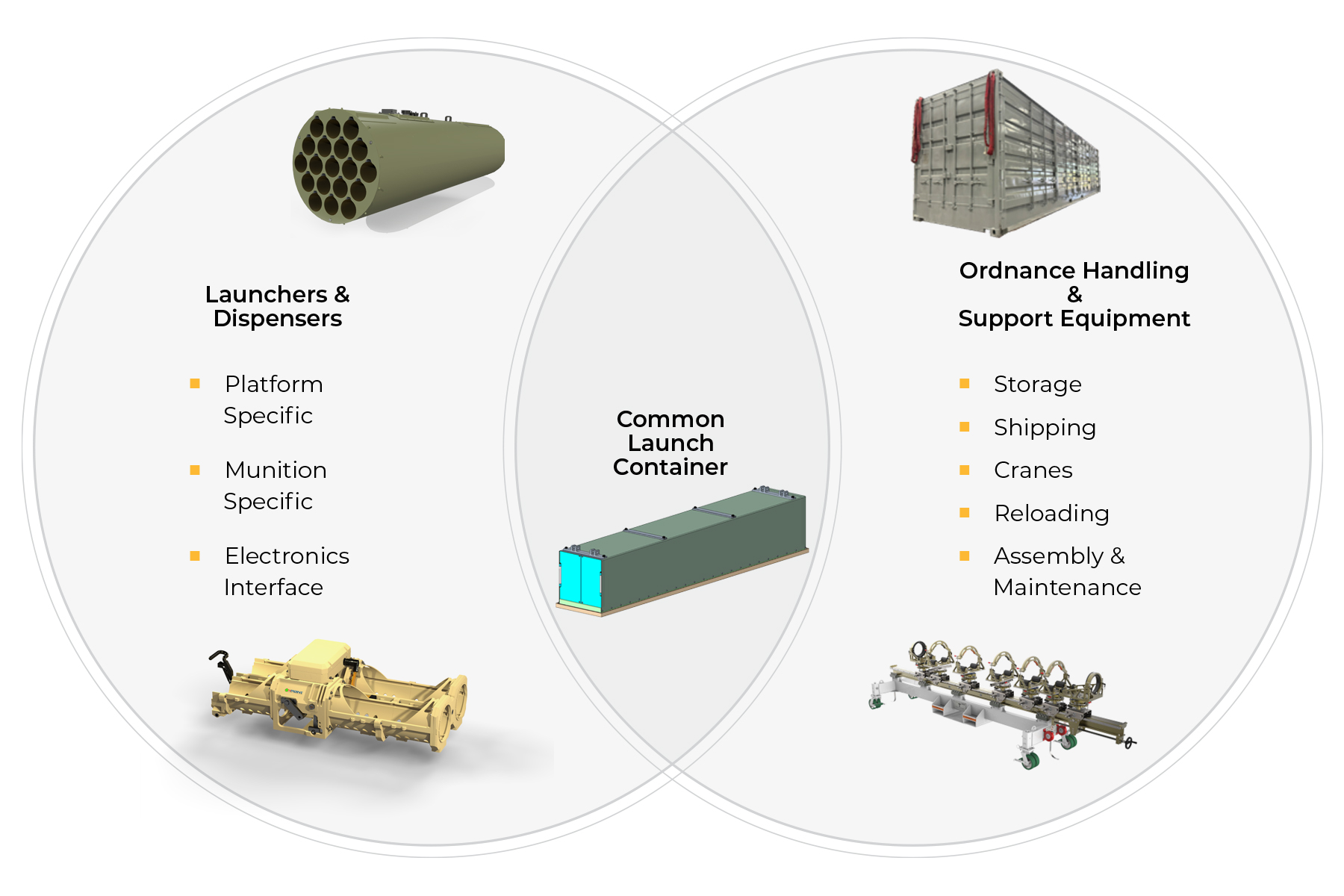

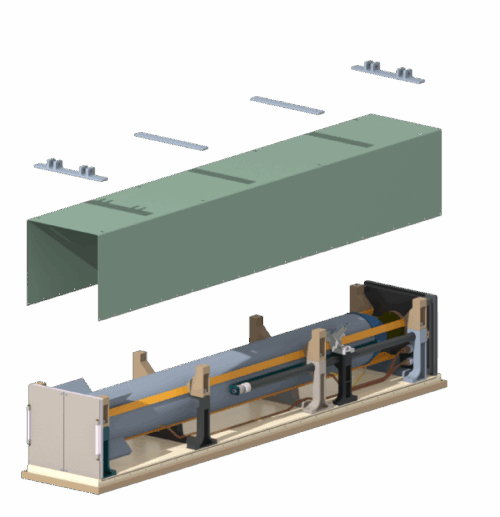

Common Launch Containers

McCormick Stevenson offers a combined Shipping & Launch Container System that supports transport, storage, deployment, and launch in a single container.

Common Launch Containers

McCormick Stevenson offers a combined Shipping & Launch Container System that supports transport, storage, deployment, and launch in a single container.

Features

- Fire Control & Munition interface adaptability

- Flexible ejector modules tailored to launch speed/force requirements

- Integrated shock and vibration isolation

- Scalable container family for munitions in 100lb, 200lb, 500lb, and 1000lb classes

Benefits

- Eliminates separate PHS&T materials

- Reduces handling time

- Lowers delivered cost

- Enhances operational flexibility

- Stackable, efficient storage

Munitions Support Equipment

Munitions Support Equipment

Assembly & Maintenance Equipment

McCormick Stevenson designs and delivers specialized equipment to support munitions handling with safety, precision, and efficiency. Our solutions include assembly dollies and adjustable cradles for missile motors, warheads, and guidance sections, featuring rack-and-pinion systems for controlled mating of subassemblies. Rollers and rotating cradles allow for precise alignment and ease of maintenance, while non-marring surfaces and anti-static chains ensure safe handling of energetic materials. Each system is engineered with a 3X factor of safety and can be hand-rolled or forklift-moved for flexibility in operations.

Fixtures & Handling Solutions

We provide turn-key design and build services for maintenance, handling, and manufacturing fixtures, delivering customized solutions that meet specific customer requirements.

Launcher Reloading

Looking ahead, McCormick Stevenson is actively advancing automated rearming and reloading capabilities for both Army and Navy launchers.

Let’s Design & Build for Your Mission:

Contact us today to explore configuration options, compliance details, or technical walkthroughs related to ordnance or shipboard use.

Let’s Design & Build for Your Mission:

Contact us today to explore configuration options, compliance details, or technical walkthroughs related to ordnance or shipboard use.