Development Engineering

Development Engineering

McCormick Stevenson offers a wide range of mechanical engineering expertise; from deep systems engineering to routine drafting and design, and everything in-between. We help reduce your program risk through clear requirements definition, flexible contract engagements, and the immediate application of a qualified and experienced staff. We tailor our work products to your internal systems and processes. McCormick Stevenson also exercises rigorous cybersecurity practices. We always protect your sensitive data and intellectual property.

We stand ready to partner whenever a critical need arises. Look to the McCormick Stevenson team for a well-honed engineering toolset that brings solutions and success.

- Accelerate programs with experienced armament systems engineers and designers

- Identify, manage, and mitigate program risk

- Optimize system Size, Weight, Power, and Cost (SWaP-C)

- Ensure product survival under shock and vibration

- Ensure Hi-G gun-launch survivability

- Ensure steady state and transient performance at temperature extremes

- Reduce cost through design for manufacturing and assembly

- Develop and deliver product Technical Data Packages (TDPs)

- Develop virtual and physical prototypes of products

- Access, identify, and track system requirements and associated Verification and Validation Plans

- Manage and execute system test and qualification

- Integrate products into land, air, and maritime platforms

- Develop and deliver custom tooling, fixtures, and equipment to support products

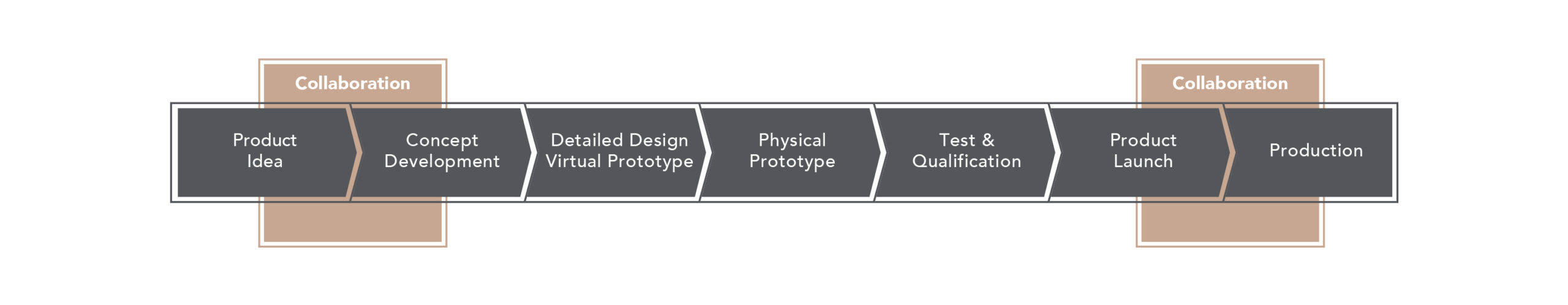

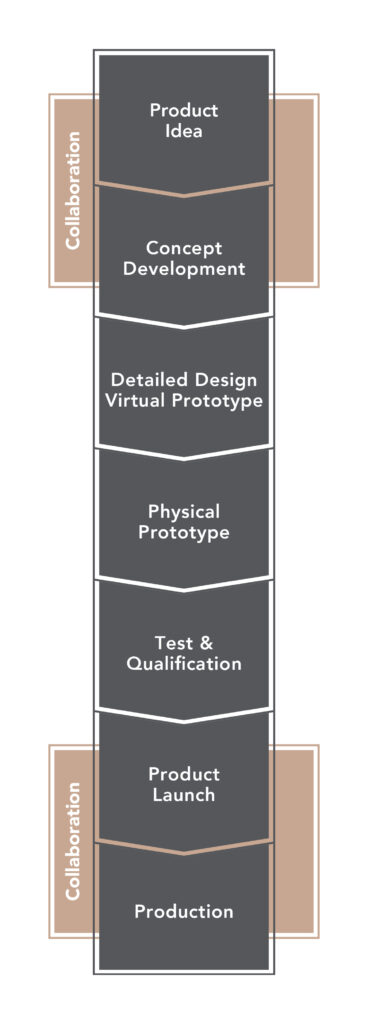

Expertise Across the Entire Product Development Cycle

Look to McCormick Stevenson as your mechanical engineering partner. We can help with your entire product development process or assist at any stage to address your specific challenges.

Ensure success through clearly defined requirements, tightly coupled to verification and validation plans.

- Proposal Development

- Requirements Development

- System Synthesis

- Baseline Definition

- Risk Management and Mitigation

- Configuration Management

- Model Based Systems Engineering

Move quickly to production revenue by leveraging our design expertise.

- Interface Control Documentation

- Concept Development

- Trade Studies

- 3-D Solid Modeling

- Drafting and Documentation

- Design for Manufacturing / Design for Assembly

- Cabling

- Type 2D and 3D Technical Data Packages per MIL-STD-31000

Successfully test and qualify through selective physical prototyping.

- Prototype Fabrication

- Rapid Component Sourcing

- 3-D Printing

- System Integration

- Laboratory and Field Integration

- Platform Integration

- Custom Storage and Transport Cases

Breeze through integration and test with elegant virtual prototypes.

- Finite Element Methods Analysis (FEA)

- Structures

- Heat Transfer

- Computational Fluid Dynamics Analysis (CFD)

- Internal Flows

- External Flows

- Failure Analysis

- Tolerance Analysis

- Interior Ballistics

- Exterior Ballistics

We satisfy every requirement, or we’re not done.

- Test Plan Development

- Test System Development

- Structural and Thermal Analysis Correlation

- Test Program Management and Execution